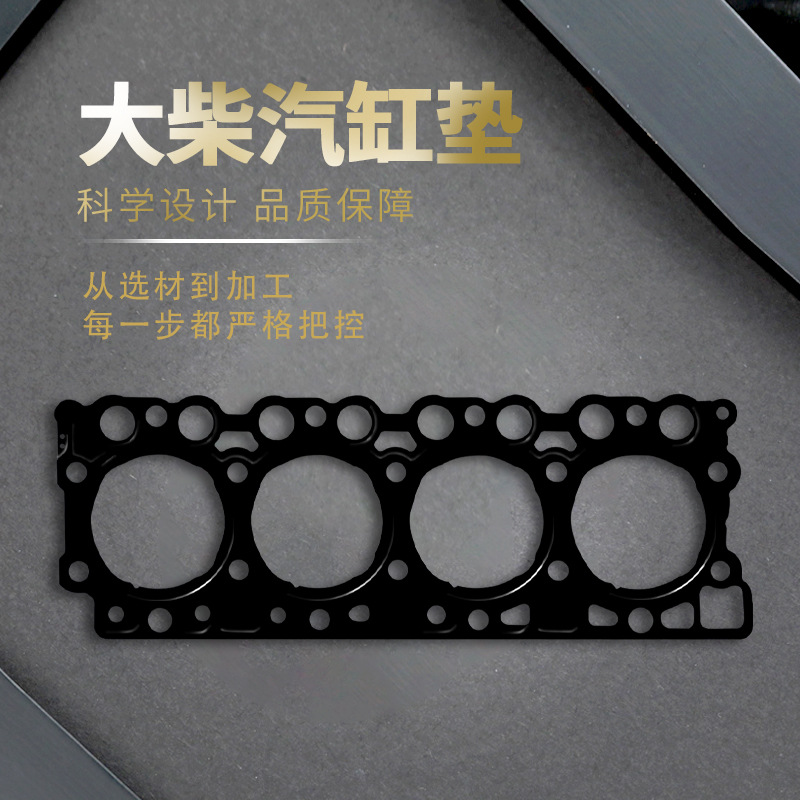

Strict selection of materials ensures excellent performance

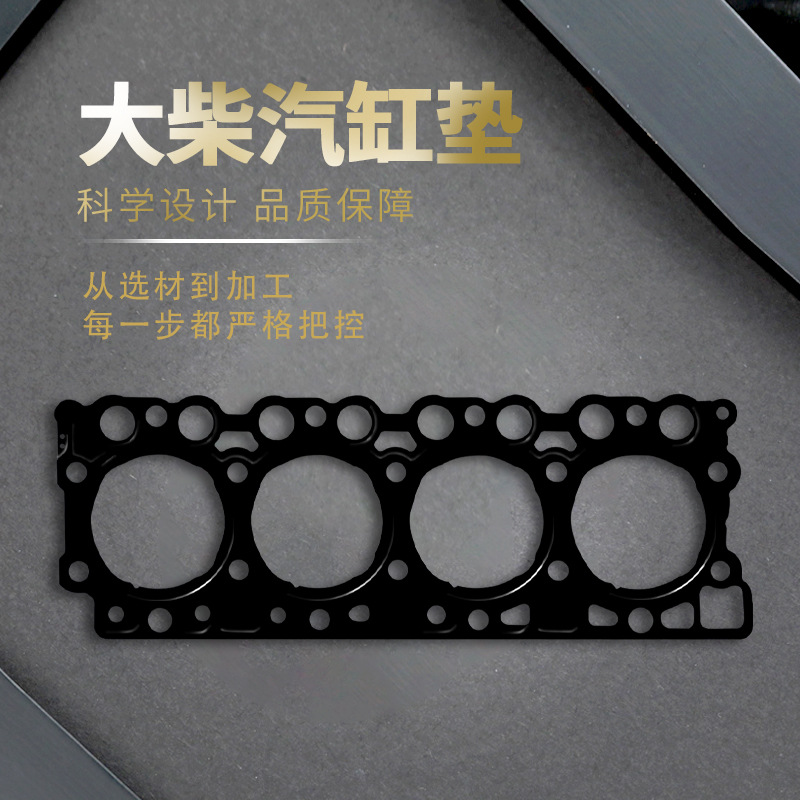

In the pursuit of high performance, we never stop exploring the footsteps. In order to create a reliable cylinder head gasket, the manufacturer has carefully selected a variety of high-quality material combinations-high-strength alloys and special rubber compounds. These two core components not only give the product extremely high mechanical strength, but also enable it to maintain excellent sealing performance under extreme temperature and pressure conditions.

The choice of these particular materials is not accidental, but is based on years of research and technological accumulation. Through numerous tests, the final optimal formula can not only meet the current market demand, but also lay a solid foundation for future technological innovation. Laboratory data show that in the test under simulated harsh conditions, this batch of new products showed excellent stability, far exceeding the industry average.

Strict selection of materials ensures superior performance

Strict selection of materials ensures superior performance

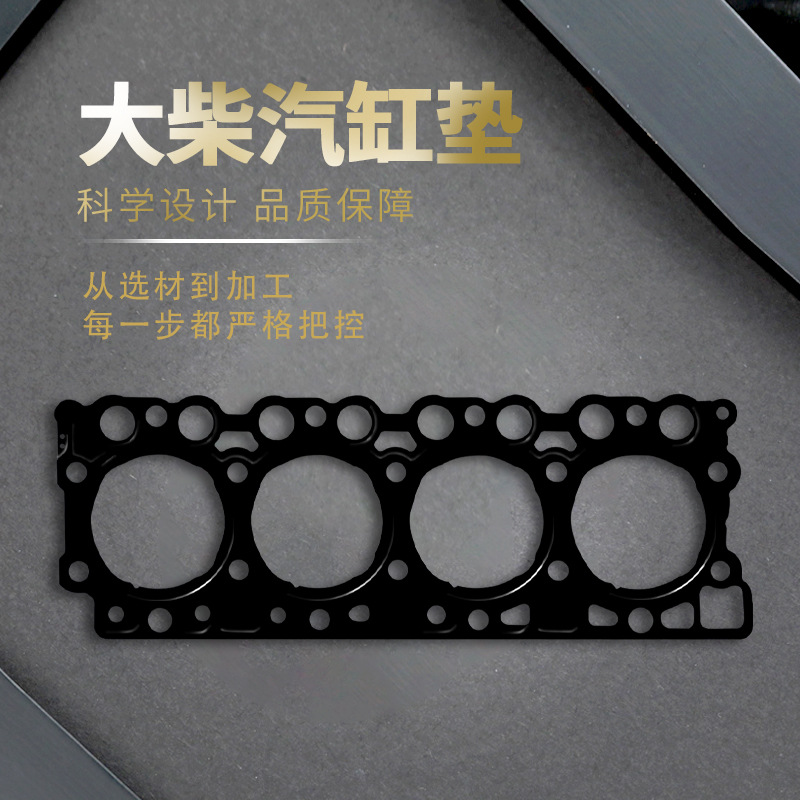

Accurate adaptation to a variety of diesel models

Facing the dazzling array of diesel engine models on the market, how to achieve seamless docking? The answer lies in this multifunctional cylinder head gasket. It can perfectly fit the main product lines of many well-known brands, including but not limited to Daichai 6DK, 4DK, 56D and Deutz 52D series imported from Germany. Each version has its own unique features to suit the needs of different application scenarios.

For example, for high-horsepower engines (such as 6DK) that are often in high-load operation, the designer has specially strengthened the edge reinforcement design to effectively prevent loosening caused by vibration. For those small-power units that start and stop frequently, a more flexible and soft elastic interface structure is introduced to ensure that every cold and heat alternation will not cause damage.

Accurate adaptation to multiple diesel models

Accurate adaptation to multiple diesel models

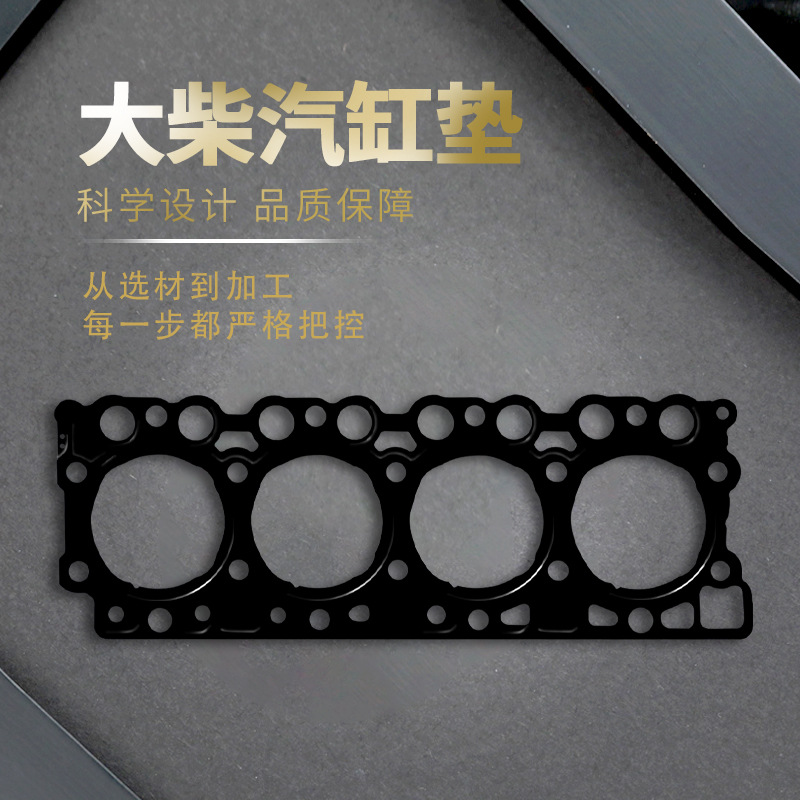

Escort with strict quality control system

From the initial selection of raw materials to the final storage of finished products, every link is closely monitored. The company has established a sound quality management system, covering the assessment of key indicators at all nodes of the whole process. These include a series of complex processes such as dimensional tolerance inspection accurate to the millimeter level, detailed appearance defect inspection, and even pressure leak testing to simulate real working scenes.

With this set of scientifically rigorous methodological guidelines, we have successfully intercepted the occurrence of many potential risk events in the past few years. A routine inspection found a slight deviation in a certain batch, immediately start the emergency plan for a comprehensive review until the hidden dangers are completely eliminated before resuming the production process. Not only that, but also obtained a number of international authorities issued by the quality certification, to provide users with a double security.

Escort with strict quality control system

Escort with strict quality control system

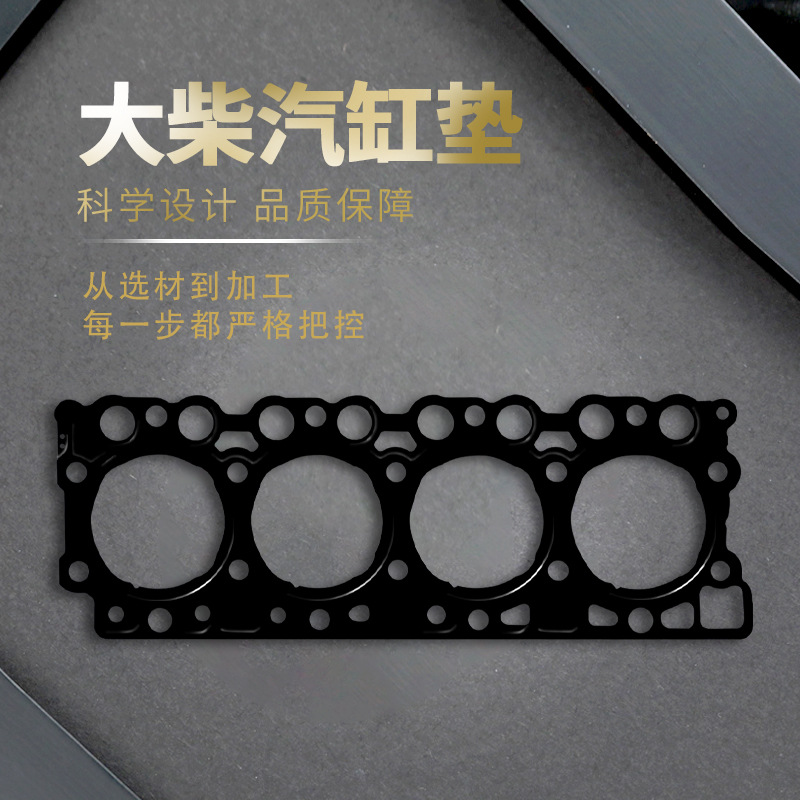

Long-life design reduces maintenance costs

As the use time increases, any mechanical equipment will face a certain degree of aging. But for this cylinder head gasket, this process has been greatly delayed. Thanks to the latest generation of anti-corrosion coating technology and the application of antioxidant additives, it remains strong even after thousands of hours of uninterrupted work.

Market research shows that our customers can often enjoy more than three times the service life compared to the traditional concept that similar competitors need to be replaced every two years on average. This means that not only can the maintenance frequency be greatly reduced, but also the related cost can be significantly saved in the whole life cycle. Of course, regular professional care is still essential, and correctly following the instructions will help further extend the service period.

Long-life design reduces maintenance costs

Long-life design reduces maintenance costs

Convenient and efficient customer service support

Quality after-sales service is one of the important weights to win reputation. Whether it is pre-consultation or post-follow-up, we are committed to providing a comprehensive support network. Have an experienced online customer service team on standby around the clock to answer all kinds of questions and puzzles in a timely manner; set up a dedicated telephone to facilitate instant communication; at the same time, open an e-mail service platform for written message feedback.

Especially in the case of sudden failure or urgent supply of spare parts, the rapid response mechanism plays a great role. Once an old customer in a remote area suffered an unexpected power outage. The required accessories were airlifted to the site and the repair task was successfully completed within two days after contacting us for help. Many similar examples show the peace of mind brought by the level of specialization.

Convenient and efficient customer service support

Convenient and efficient customer service support

The concept of green environmental protection runs through the whole process

Under the global trend of advocating energy conservation and emission reduction, corporate social responsibility awareness is becoming more and more important. "Green" has become a new benchmark to measure whether an excellent manufacturing manufacturer is qualified. As early as the beginning of product development, we put environmental protection in the first place, and strive to meet the functional requirements and minimize the impact on the natural environment.

Specific measures are reflected in all aspects: