In the industrial field and transportation industry, diesel engines are favored for their strong power output and high reliability. However, in order to make these "power heart" long-term stable operation, a high-quality cylinder head gasket is essential. Today we will discuss the importance of cylinder head gasket and how to choose the right cylinder head gasket.

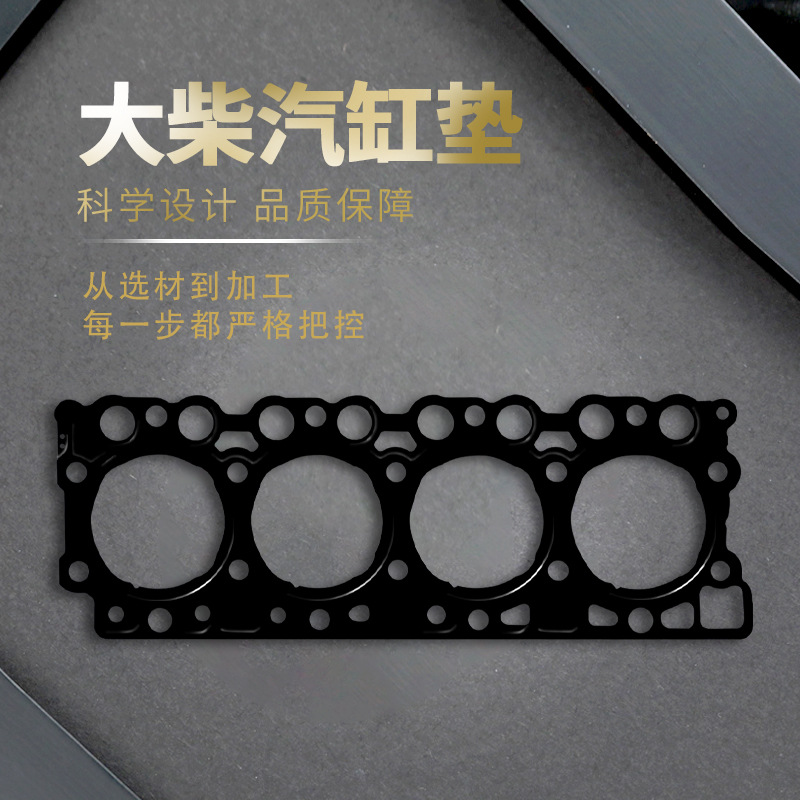

The cylinder head gasket is one of the key components connecting the crankcase and the cylinder head. It not only plays the role of heat insulation and leakage prevention, but also ensures that the gas in the combustion chamber will not leak to the external environment. In addition, excellent sealing performance can also reduce oil consumption, thereby protecting the entire engine from unnecessary wear damage.

When it comes to reliable cylinder gaskets, Daichai and Deutz are the market leaders. These two brands have won the trust of global users with years of technology accumulation and strict manufacturing standards. Daichai series products such as 6DK, 4DK and 56D have been specially optimized for different types of mechanical equipment. The 52D model under Deutz is famous for adapting to harsh working conditions and can meet the harsh requirements of heavy trucks or construction machinery for durability.

Further comparison shows that Dachai 6DK is suitable for high-horsepower commercial vehicles and has super heat resistance and compressive strength. In contrast, Dachai 4DK is more suitable for small and medium-sized diesel engines, taking into account the cost performance while providing stable performance. As for the Dachai 56D, it is specially developed for special equipment used in special operating environments. On the other hand, the Deutz 52D is made of advanced composite materials and can maintain excellent working conditions under extreme temperature conditions.

The positive feedback from many customers proves the strength of these two manufacturers. "Since the replacement of the cylinder head gasket of the Dai Chai brand, my truck has never stalled due to leakage." A driver from the logistics industry said, "and it is very convenient and quick to install!" Another owner of an excavator added: "Our machinery is exposed to the sun and rain all year round, but since using Deutz's products, the frequency of failures has dropped significantly."

So, in the face of so many choices, how to decide which one is the most suitable for you? The first thing you need to know is the parameter information of the model you are using, such as displacement size or working pressure range, etc. Secondly, consider the specific conditions of use-if you are often in a high-temperature and high-pressure environment, it is recommended to give priority to high-end options like Deutz; for ordinary family cars, the affordable and well-known Dai Chai may be a better partner.