In the operation of modern machinery, the cylinder head gasket is a key component connecting the engine block and the cylinder head, and its role cannot be underestimated. Its main task is to maintain air tightness in a high temperature and high pressure environment, and to prevent gas leakage, coolant penetration and lubricating oil leakage.

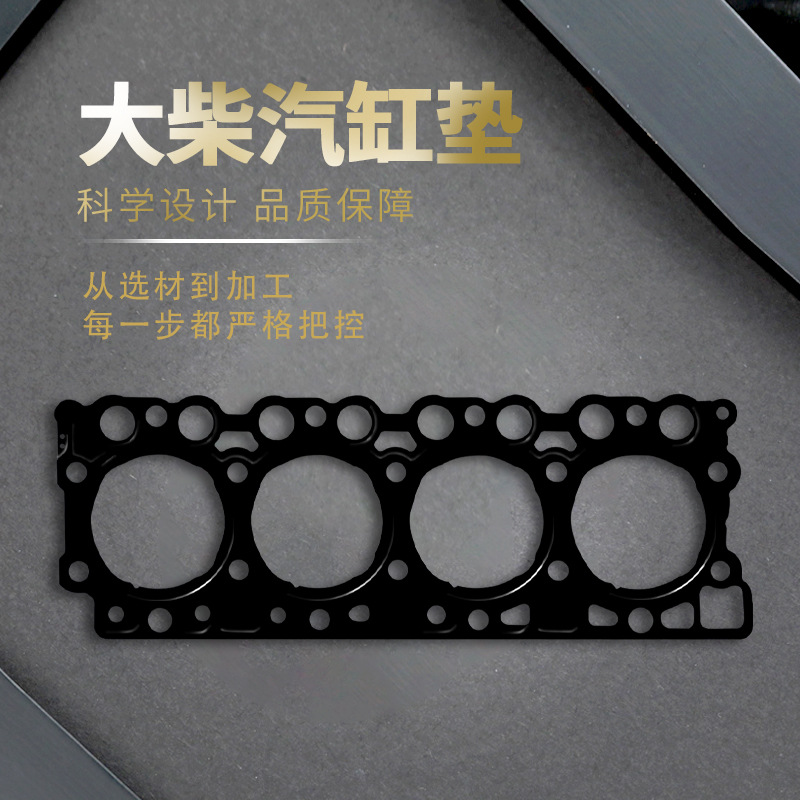

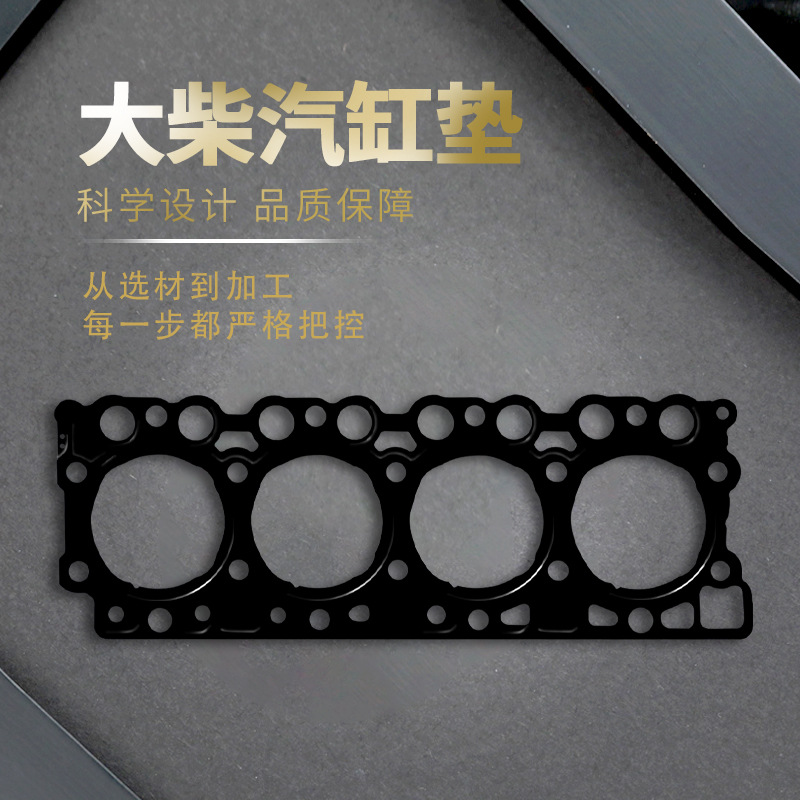

For the pursuit of high performance of industrial users, choose the right cylinder head gasket is essential. Take the Dai Chai brand as an example, it covers a number of product lines suitable for different models, including the highly respected 6DK, 4DK and 56D models. Each version is optimized for a specific type of engine, such as the use of enhanced materials or improved geometric structure design, etc., to meet the needs of various complex conditions.

In addition to the traditional Daichai series, we have specially introduced the Deutz 52D model, which is specially designed for use with German power units. This new product inherits the traditional advantages of European precision machining, and combines the needs of the local market to complete further technological innovation and upgrading. Compared with similar competitors, it has better thermal stability and corrosion resistance, and can still maintain a stable level of performance under long-term continuous operating conditions.

In order to provide customers with the most reliable parts support, our R & D team has always put "quality first" in the first place, taking into account every detail to implement in place. From the raw material screening link began to strictly control the checkpoint, only select the international certification standards above the metal plate for follow-up process operation; Then through the advanced automated production equipment to complete the precise cutting molding steps after the inspection qualified can be put into storage for sale.

Of course, no amount of theoretical explanations are as convincing as the real user's voice. Many loyal customers have expressed their high recognition of the products they buy. "Since changing to the new model of your recommend, the machine has obviously felt much smoother." A maintenance technician from the southern region said, "and even after a whole year of high-intensity testing, there was no failure!" There are many positive comments like this...

then how can we accurately select the ideal configuration that is most suitable for our own equipment conditions? First of all, we need to clearly understand the specific model parameter information (such as displacement size, compression ratio value range, etc.) currently in service, and then match the corresponding specifications one by one against the official selection instruction manual, which can be easily done ~ In addition, we remind everyone to pay attention to check whether there are clearly marked relevant technical indicators on the packaging logo!