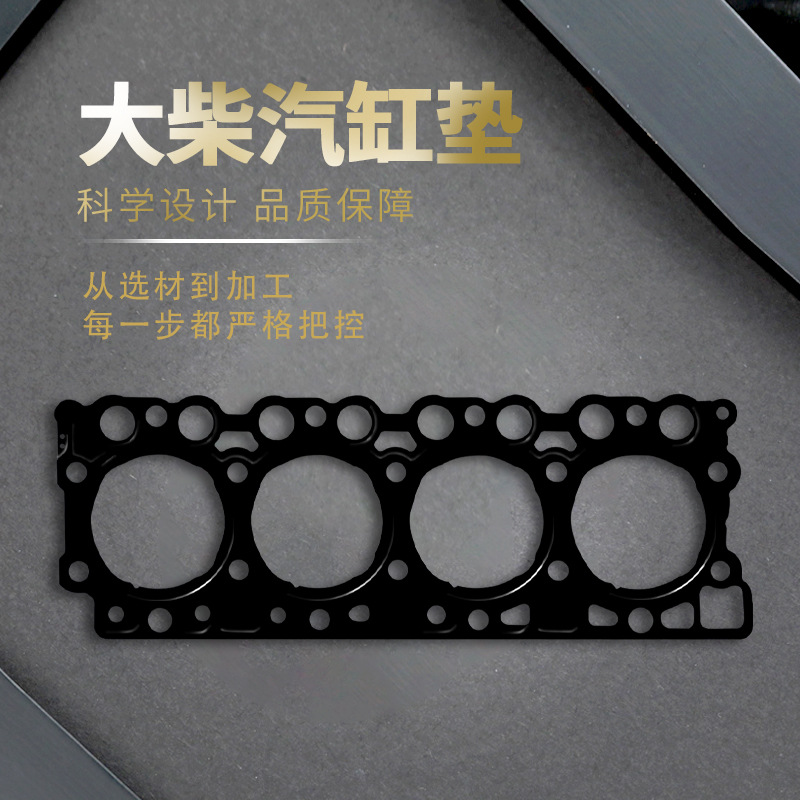

Everything You Need to Know About Daichai Cylinder Pads – Daichai 6DK, 4DK, 56D & Deutz 52D

When it comes to the smooth and reliable operation of an engine, there are many components that play a vital role behind the scenes. One such unsung hero is the cylinder pad — a small yet critical part that ensures the integrity of the combustion chamber and the longevity of the entire engine system. In this article, we dive deep into the world of Daichai cylinder pads, exploring the key models — 6DK, 4DK, 56D — and their Deutz counterpart, the 52D. Whether you're a mechanic, equipment operator, or industrial engineer, this guide will give you a comprehensive understanding of these essential components.

Why Cylinder Pads Should Never Be Overlooked — The Engine's Silent Guardian

At first glance, a cylinder pad might seem like a simple gasket, but its role is far more complex than it appears. This component seals the gap between the engine block and the cylinder head, ensuring that combustion pressure is contained and that coolant and oil do not leak into the combustion chamber. Without a high-quality pad, the engine’s performance can degrade rapidly, leading to overheating, loss of power, and even catastrophic failure.

The importance of using durable, well-engineered cylinder pads becomes even more apparent in industrial and heavy-duty applications. These environments demand consistent performance under extreme conditions, making the choice of pad not just a maintenance detail, but a crucial decision that affects the overall efficiency and lifespan of the engine.

Daichai and Deutz — A Legacy of Precision and Compatibility

Daichai and Deutz are two names that have long been associated with excellence in engine manufacturing. While Daichai is known for its robust industrial diesel engines, Deutz has built a reputation on reliability and precision engineering. Despite being separate brands, many of their engine models share design similarities, especially in cylinder head configurations, which is why Daichai and Deutz cylinder pads are often used interchangeably in certain applications.

This compatibility is not just a matter of convenience; it reflects a shared commitment to quality and standardization in engineering. Whether you're working with a Daichai or a Deutz engine, choosing a cylinder pad from either brand ensures a perfect fit and optimal sealing performance.

Model Breakdown — 6DK, 4DK, 56D, and 52D

Each cylinder pad model is designed with specific engine types and applications in mind. The Daichai 6DK is often found in large, high-output engines used in construction and agricultural machinery, where durability and heat resistance are paramount. Meanwhile, the 4DK is tailored for more compact engines, offering a balance between performance and space efficiency, making it ideal for smaller generators and mobile equipment.

The Daichai 56D and Deutz 52D models, while similar in many ways, cater to slightly different engine lineups. Both are engineered for mid-range diesel engines, providing reliable sealing under a variety of operating conditions. Choosing between them often comes down to the specific engine model and availability, but rest assured, both are built to the same high standards of quality and performance.

More Than Just a Seal — The Science Behind Cylinder Pad Performance

Modern cylinder pads are marvels of material science. They must withstand extreme temperatures, pressures, and chemical exposure without degrading. High-quality pads like the Daichai and Deutz models are constructed using multi-layer steel (MLS) or composite materials that offer superior thermal resistance and structural integrity. This ensures that even under the most demanding conditions, the pad maintains a tight seal and prevents harmful leaks.

Furthermore, a well-sealed combustion chamber directly affects engine efficiency. Poor sealing can lead to incomplete combustion, reduced fuel economy, and increased emissions — all of which are critical factors in industrial and commercial applications.

Signs Your Cylinder Pad is Failing

Identifying a failing cylinder pad early can save you from costly repairs. Common symptoms include white smoke from the exhaust, coolant in the oil (resulting in a milky appearance), engine overheating, and a noticeable drop in performance. These signs are often mistaken for other engine issues, so it’s crucial to conduct a thorough inspection if you suspect a problem with the pad.

Replacing a worn or damaged pad before it fails completely is far more cost-effective than dealing with the aftermath of a blown gasket, which can include warped cylinder heads and internal engine damage.

Installation Tips from the Pros

Proper installation is as important as choosing the right pad. One of the most common mistakes is incorrect torque application — either over-tightening or under-tightening the bolts can compromise the seal and damage the pad. It’s essential to follow the manufacturer’s specifications for torque settings and tightening sequences.

Before installation, always inspect the mating surfaces of the engine block and cylinder head for warping or debris. A clean, flat surface is vital for a secure fit. Also, never reuse old head bolts unless they are specifically designed for multiple use — doing so can lead to uneven pressure and premature failure.

How to Spot the Real Deal

With so many counterfeit parts on the market, it's important to know how to identify genuine Daichai and Deutz cylinder pads. Look for clear, sharp branding on the packaging and the pad itself. Genuine products will have consistent material thickness, precise cutouts, and a clean, professional finish. Avoid pads that feel flimsy or have irregular edges.

Purchase from authorized distributors or trusted suppliers to ensure authenticity. Check for certification labels or QR codes that can be scanned for product verification.

Real-World Feedback — What Technicians Are Saying

Feedback from users in the field consistently highlights the reliability and durability of Daichai and Deutz cylinder pads. Many mechanics praise the 6DK for its resilience in high-stress environments, while the 4DK earns high marks for its ease of installation and adaptability. Users across agriculture, construction, and power generation sectors report fewer replacements and consistent performance over time, making these pads a favorite among professionals.

Maximizing Lifespan — Maintenance Tips You Can’t Ignore

While cylinder pads are built to last, certain maintenance practices can significantly extend their life. Regularly checking and maintaining the cooling system is essential — overheating is one of the leading causes of pad failure. Additionally, avoiding sudden engine shutdowns after heavy use and allowing the engine to warm up properly can reduce thermal stress on the pad.

Keeping up with scheduled maintenance and monitoring oil and coolant levels also contributes to a healthier engine environment, reducing the risk of premature pad wear.

What’s Next for Cylinder Pad Technology?

As engines become more advanced and environmental regulations tighten, the future of cylinder pad design is leaning toward higher performance and sustainability. New materials such as advanced composites and nano-coatings are being explored to improve thermal resistance and reduce emissions. Additionally, smart diagnostics may soon play a role in pad maintenance, allowing for real-time monitoring of engine conditions and predictive replacement schedules.

Conclusion

Whether you're working on a Daichai 6DK, 4DK, 56D, or a Deutz 52D engine, choosing the right cylinder pad is not just about sealing a gap — it's about ensuring the heart of your engine runs smoothly for years to come. With the right knowledge, installation technique, and maintenance habits, you can keep your machinery performing at its peak while avoiding costly downtime.