When it comes to engine performance and longevity, certain components often fly under the radar — quietly working behind the scenes to keep everything running smoothly. Among these unsung heroes, the cylinder pad plays a crucial role in maintaining engine integrity. For owners and operators of Daichai 6DK, 4DK, 56D, and Deutz 52D engines, choosing the right cylinder pad is not just a maintenance detail — it’s a strategic decision that can significantly impact reliability, efficiency, and long-term cost of ownership.

The Hidden Hero in Engine Performance: Meet the Cylinder Pad

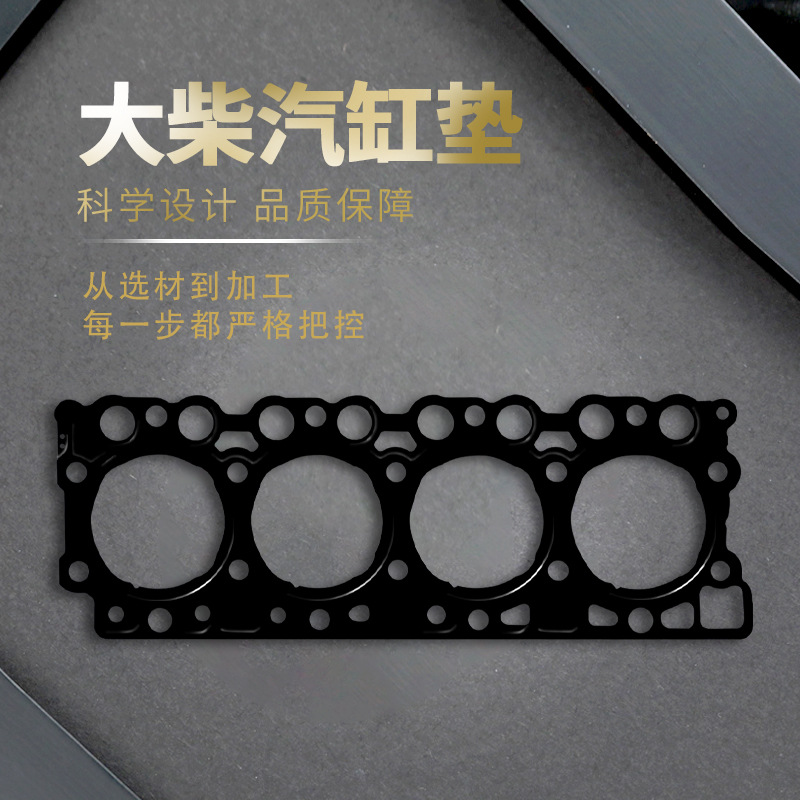

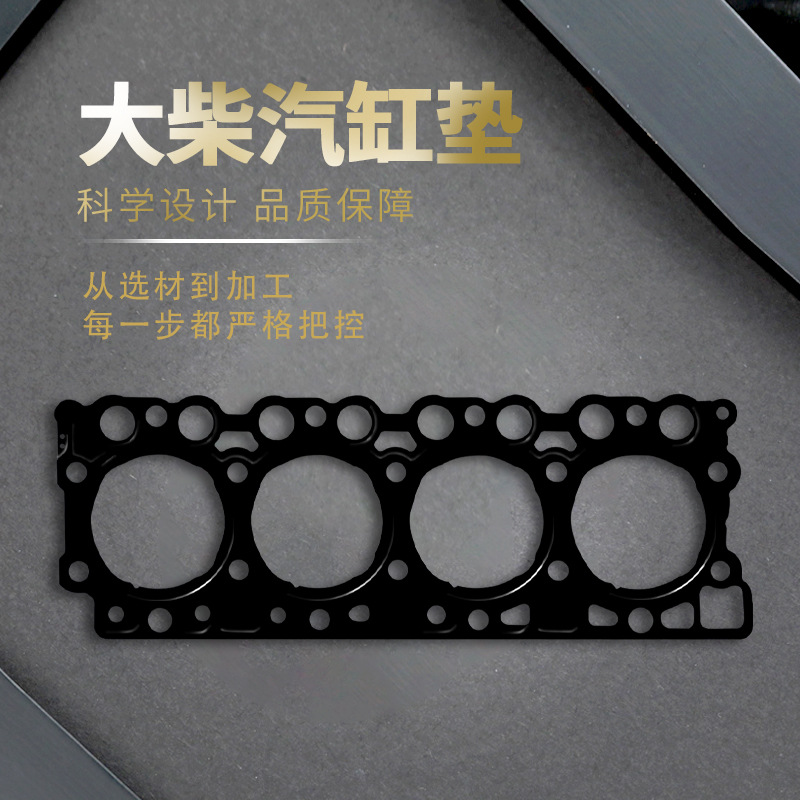

At first glance, a cylinder pad might seem like a simple metal gasket, but its function is anything but basic. It sits between the engine block and cylinder head, creating a tight seal that prevents coolant and oil leaks while maintaining the necessary compression for combustion. In high-performance and industrial engines like the Daichai 6DK or Deutz 52D, the demands placed on this component are immense. A subpar cylinder pad can lead to catastrophic engine failure, making the choice of material and design critically important.

Direct Daichai Cylinder Pads are engineered to withstand the extreme pressures and temperatures generated by these powerful engines. Unlike generic or aftermarket alternatives, these pads are designed with precision to ensure a perfect fit and optimal performance under real-world conditions.

What Sets Direct Daichai Cylinder Pads Apart?

One of the key differentiators of Direct Daichai Cylinder Pads is their construction. These components are crafted from high-grade metal alloys and feature multi-layered sealing technologies that offer superior resistance to thermal expansion and mechanical stress. This is especially important in engines like the Daichai 4DK, which are often used in heavy-duty applications where temperature fluctuations are frequent and intense.

Beyond material quality, the manufacturing process also plays a crucial role. Direct Daichai Cylinder Pads undergo stringent quality control procedures to ensure dimensional accuracy and surface finish consistency. This precision ensures that each pad fits perfectly and functions as intended, eliminating the risk of misalignment or uneven compression that can lead to early failure.

Why Your Engine Model Matters: 6DK, 4DK, 56D & Deutz 52D Breakdown

Each engine model has unique design characteristics that influence the type of cylinder pad it requires. For instance, the Daichai 6DK features a larger combustion chamber and higher compression ratios compared to the 4DK, making it more susceptible to thermal stress. The Deutz 52D, on the other hand, is commonly used in marine and industrial applications, where corrosion resistance and sealing integrity are of utmost importance.

Direct Daichai Cylinder Pads are specifically tailored for each of these models. Whether it's the 56D used in agricultural machinery or the Deutz 52D found in power generation systems, each pad is designed to meet the specific sealing and durability requirements of the engine. Choosing the correct pad for your model ensures optimal performance and reduces the risk of costly repairs down the line.

The Real Cost of Cutting Corners: What Happens Without the Right Cylinder Pad

While it might be tempting to opt for cheaper alternatives, the long-term consequences of using inferior cylinder pads can be severe. Poor sealing can lead to coolant leakage into the combustion chamber, causing hydrolock and severe engine damage. Oil contamination and loss of compression can also result in reduced power output, increased fuel consumption, and excessive emissions.

More importantly, replacing a failed cylinder pad is not a simple task. It often requires disassembling major engine components, leading to significant labor costs and downtime. Investing in a high-quality Direct Daichai Cylinder Pad upfront can save thousands in repair costs and ensure your engine continues to perform reliably for years.

Performance Meets Longevity: How Direct Daichai Cylinder Pads Deliver Both

One of the most notable benefits of using Direct Daichai Cylinder Pads is the improvement in overall engine performance. The superior sealing technology ensures consistent compression, which directly translates to better fuel efficiency and smoother engine operation. Additionally, the enhanced thermal resistance reduces the likelihood of head warping and stress fractures, which are common in high-load environments.

Users of engines like the Daichai 6DK have reported noticeable improvements in engine startup, idle stability, and throttle response after upgrading to Direct Daichai Cylinder Pads. Many operators in the agricultural and construction sectors have praised the durability of these pads, with some reporting no signs of wear even after thousands of operating hours.

Installation Made Easy: Tips for Getting the Most Out of Your Cylinder Pad

Proper installation is just as important as the quality of the pad itself. Before fitting a new cylinder pad, it's crucial to inspect the mating surfaces for flatness and cleanliness. Any warping or debris can compromise the seal and lead to premature failure. Torque specifications should also be followed precisely to avoid over-tightening, which can damage the pad or the cylinder head.

Signs that a cylinder pad may need replacement include white smoke from the exhaust, coolant loss without visible leaks, or a noticeable drop in engine power. If you're unsure whether a pad is the culprit, it’s always best to consult a professional mechanic or refer to the manufacturer's guidelines.

Behind the Scenes: Manufacturing Excellence at Daichai

Direct Daichai Cylinder Pads are not just another generic part — they are the result of years of engineering expertise and rigorous quality assurance. Each pad is manufactured in state-of-the-art facilities using advanced CNC machining and laser inspection technologies to ensure every unit meets exacting standards.

From raw material selection to final packaging, every step of the production process is monitored to maintain consistency and performance. This commitment to excellence is why Direct Daichai Cylinder Pads are trusted by professionals and equipment manufacturers worldwide.

From Farm to Factory: Where These Cylinder Pads Shine the Most

Whether it’s powering a tractor in the fields of rural China or driving a generator in a factory in Europe, Direct Daichai Cylinder Pads have proven their reliability across a wide range of applications. In agriculture, where uptime is critical and repairs can halt production, these pads offer the peace of mind that comes with knowing your engine is built to last.

Similarly, in the construction and marine sectors, where engines are subjected to harsh environments and heavy workloads, Direct Daichai Cylinder Pads provide the sealing strength and durability needed to keep operations running smoothly.

What the Experts Say: Mechanics and Engineers Weigh In

Many experienced mechanics and engineers emphasize the importance of using original or high-quality replacement parts when maintaining industrial engines. According to field technicians, Direct Daichai Cylinder Pads are often the first choice when replacing failed gaskets due to their reliability and compatibility.

Engineers also highlight the thoughtful design behind these pads, noting how the combination of material selection and surface treatment helps prevent corrosion and ensures long-term sealing performance — especially important in engines like the Deutz 52D that are frequently exposed to moisture and extreme conditions.

Future-Proof Your Engine: Investing in the Right Cylinder Pad Today

As engine technology evolves, so too do the demands placed on internal components. With increasingly stringent emissions standards and a push for greater fuel efficiency, the need for high-performance cylinder pads has never been more critical. Direct Daichai Cylinder Pads are designed with these future challenges in mind, offering the durability and sealing performance required to meet modern engine specifications.

By choosing Direct Daichai Cylinder Pads today, you’re not just maintaining your engine — you’re future-proofing it. These pads ensure that your Daichai 6DK, 4DK, 56D, or Deutz 52D engine continues to operate at peak performance, even as regulatory and operational demands increase.